Residual Stress Measurement

Residual stress laboratory and stress analysis center

Residual stress laboratory and stress analysis center

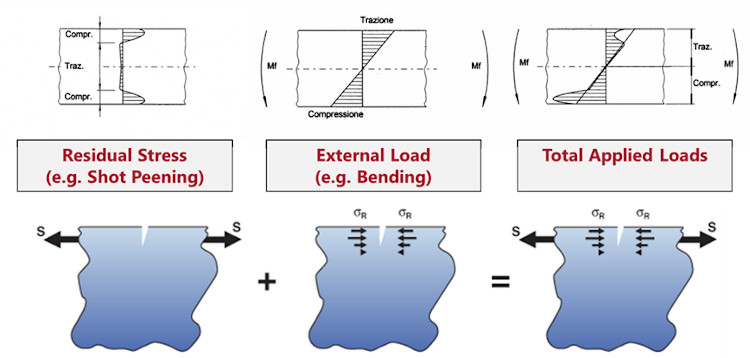

All the stresses that exist in materials are termed residual stresses.

Residual stresses can originally exist in a component and naturally add to the stresses induced by applied loads; they also can appear without the application of any external load. As a result, they can limit the loading capacity and the safety of mechanical components during operation therefore in some applications it is necessary to be able to quantify these stresses.

Moreover, residual stresses do affect the behaviour of the mechanical components and can compromise its structural and dimensional stability. For this reason, it is appropriate to carry out regular checks and tests to measure its strength.

The main issues connected with residual stresses are particularly reflected in the resistance to the mechanical fatigue and fracture of the components: the presence of residual stresses in the materials facilitates the propagation of cracks and therefore reduces the life-time of a mechanical component.

Residual stresses can be caused by the following main factors:

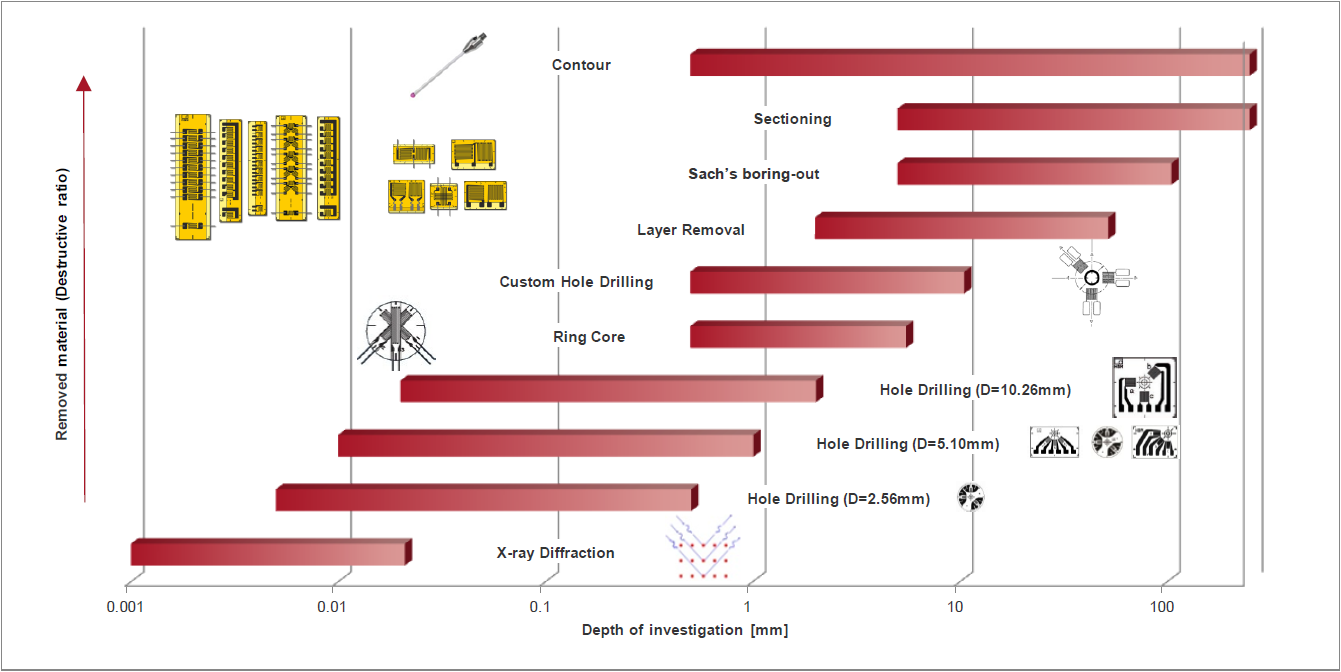

The main strain gage methods used for measuring residual stresses are:

SINT Technology is a residual stress laboratory that can offer a wide range of residual stress measurement services depending on the technical requirements of the customers. It is possible to carry out the tests both in laboratory and field conditions.

Depending on the selected technique, measurements can be performed on standard metals (Steels, Aluminum, Titanium), special engineering alloys (Nickel and Magnesium Alloy), polymeric and composite materials.

The residual stress services offered by SINT Technology can be divided into 3 groups:

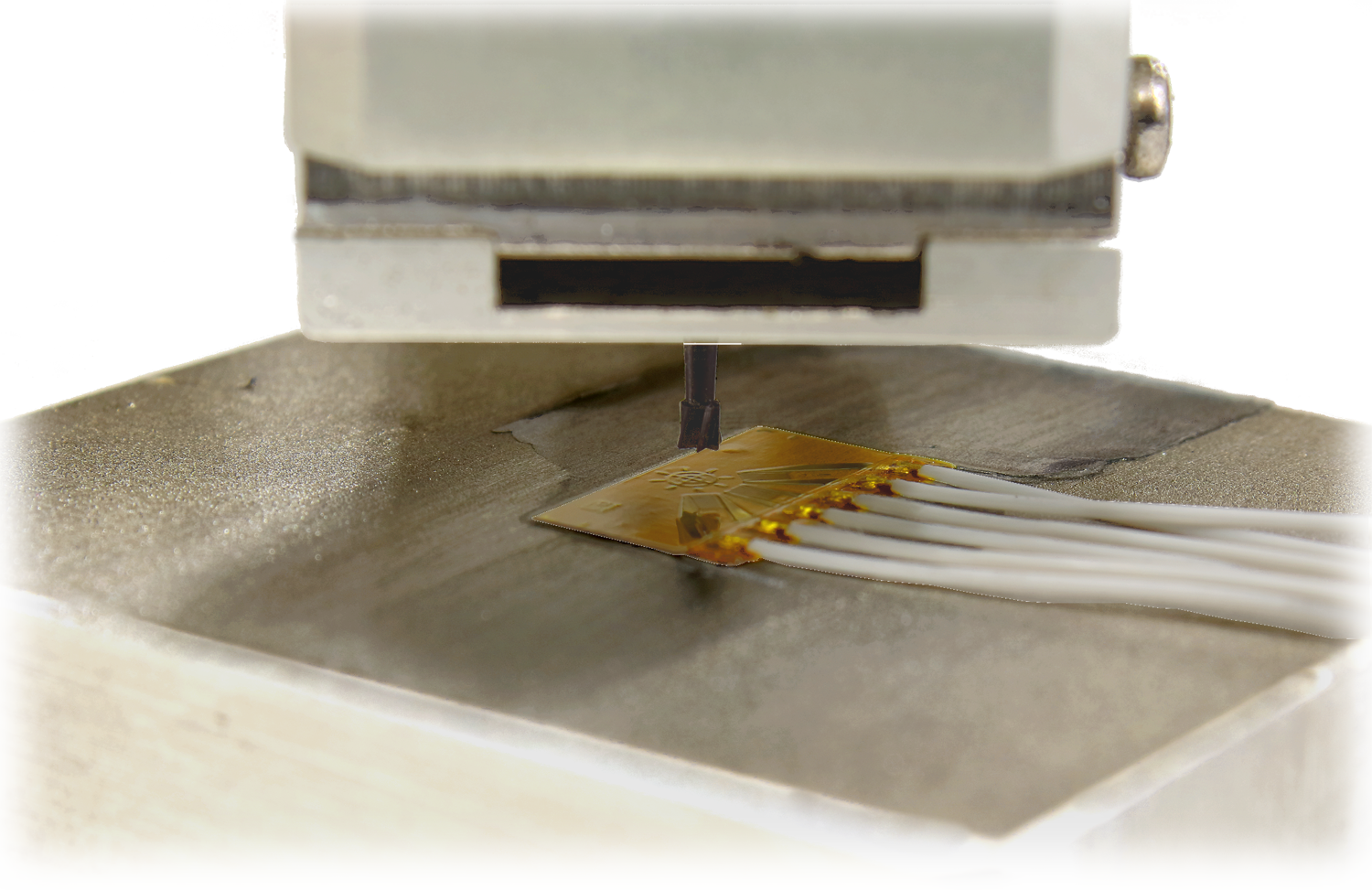

Among the semi destructive methods, the hole drilling is the less expensive and most commonly used measurement technique. The tests are carried out according to ASTM E837 standard. Different measurement layout and configuration are available in order to guarantee the compliance with the requirement of the customer in term of accuracy and total depth of analysis. SINT Technology is a ISO/IEC 17025 accredited laboratory which provides residual stress determination by the hole-drilling method, both for laboratory work and field tests.

Ring Coring is an alternative technique mainly used for residual stress measurements in which the target is the determination of the residual stresses profile up to the total depth of 5mm. For this reason, the ring-coring method is used for industrial aims for the determination of residual stresses on large size forged and casted items (shafts, compressors and turbine disks) where the calculation of residual stress on the surface is less important.

In the category of destructive methods, the laboratory of SINT technology can offer a wide range of experimental measurement services: the selection of most suitable one depends on a series of technical requirements and specifications/geometrical sizes of the workpieces. The main destructive methods using strain gage for residual stress measurement that can be offer by SINT Technology laboratory are the Layer removal, the Sach’s boring out, the Sectioning and the Slitting method. SINT Technology can also offer a dedicated measurement service using the Contour method.

Finally, regarding the non destructive methods, SINT Technology can provides measurement services using the X-ray diffraction technique (XRD). This method is generally used for all the application in which the near-surface stress can offer a sufficient answer to the costumer’s requirements.